The animation was finally completed this week. The final animation shows the engine appear from a cutaway model of a Mk14 Spitfire. The engine then rotates to reveal the pistons. As a finishing touch for the animation we decided to add some narration. It was my job to come up with the script. It is very difficult to write a script in a museum situation because of the varied audience. I did not want to make the script to complex but it needed to be informative.

The recording of the sound was very simple and all components were put together using Premiere Video editing software. With the animation complete all that we needed to do was to prepare for the presentation.

The recording of the sound was very simple and all components were put together using Premiere Video editing software. With the animation complete all that we needed to do was to prepare for the presentation.

Evaluation

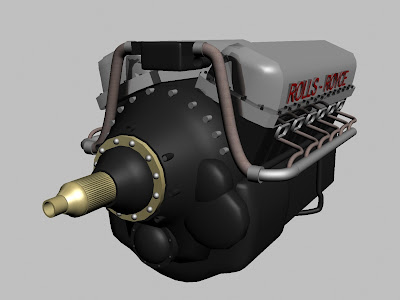

I am very happy with my contribution to this task. The Griffon engine is probably the most detailed and complicated model I have created to date. I wanted to set myself a challenge and I feel that I have succeeded. I believe that everyone in the group made some contribution to the product.

The presentation of the animation went well, and the guests from the Museum of Power seemed fairly impressed with the idea. They did have a few criticisms about the length of the animation and the content of the narration. These are both things that can be easily modified.

Overall I feel that this module has helped me grow in confidence with using 3Ds Max. I now feel I have the knowledge to tackle more complex models. I have also gained more experience working with and presenting to a client.

I am very happy with my contribution to this task. The Griffon engine is probably the most detailed and complicated model I have created to date. I wanted to set myself a challenge and I feel that I have succeeded. I believe that everyone in the group made some contribution to the product.

The presentation of the animation went well, and the guests from the Museum of Power seemed fairly impressed with the idea. They did have a few criticisms about the length of the animation and the content of the narration. These are both things that can be easily modified.

Overall I feel that this module has helped me grow in confidence with using 3Ds Max. I now feel I have the knowledge to tackle more complex models. I have also gained more experience working with and presenting to a client.

With the fairly easy task of creating the Magneto finished I moved on to producing the pipe work and wires for the whole engine. To create the pipes and spark leads I used the line tool. When drawing a line you have a variety of options. I chose to draw my lines smooth with smooth corners. In the line drawing window there is also a drop down menu labelled rendering. If you enable the box that says 'Render in viewpoint' you can set a line thickness. This is how I achieved the complex shape and bend on all of the wires. I varied the thickness depending on the application of the wire or tube. I could have used cylinders and modified them but this way is simpler and more effective.

With the fairly easy task of creating the Magneto finished I moved on to producing the pipe work and wires for the whole engine. To create the pipes and spark leads I used the line tool. When drawing a line you have a variety of options. I chose to draw my lines smooth with smooth corners. In the line drawing window there is also a drop down menu labelled rendering. If you enable the box that says 'Render in viewpoint' you can set a line thickness. This is how I achieved the complex shape and bend on all of the wires. I varied the thickness depending on the application of the wire or tube. I could have used cylinders and modified them but this way is simpler and more effective. Gear Housings

Gear Housings I also added the Rolls-Royce wording using the text tool. After writing out the words I used extrude to give the lettering depth and applied it to the covers.

I also added the Rolls-Royce wording using the text tool. After writing out the words I used extrude to give the lettering depth and applied it to the covers.

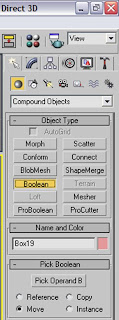

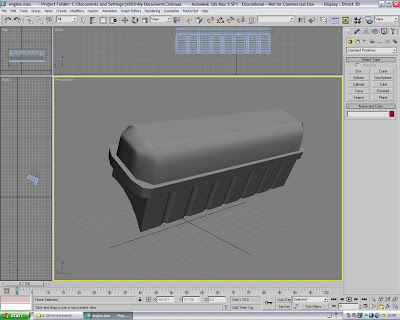

With the first side of the engine block completed I moved onto modelling the Head cover. This again started with a box shape. I altered the the number of polygons in the modify panel to make it easier to model. I then converted the shape to an editable poly and

With the first side of the engine block completed I moved onto modelling the Head cover. This again started with a box shape. I altered the the number of polygons in the modify panel to make it easier to model. I then converted the shape to an editable poly and